| Model: | CH-A12+ |

| Voltage: | AC220V/50Hz |

| Output power: | 3500W |

| Heat control: | Up to 750°C |

| Working speed: | 1-24m/min |

| Pressure: | 0.35-0.6Mpa |

| Roller width: | 20mm,30mm,40mm,50mm |

| Machine dimension: | 1600 x 650 x 1500mm |

| Net Weight: | 245 Kg |

| Inquiry |

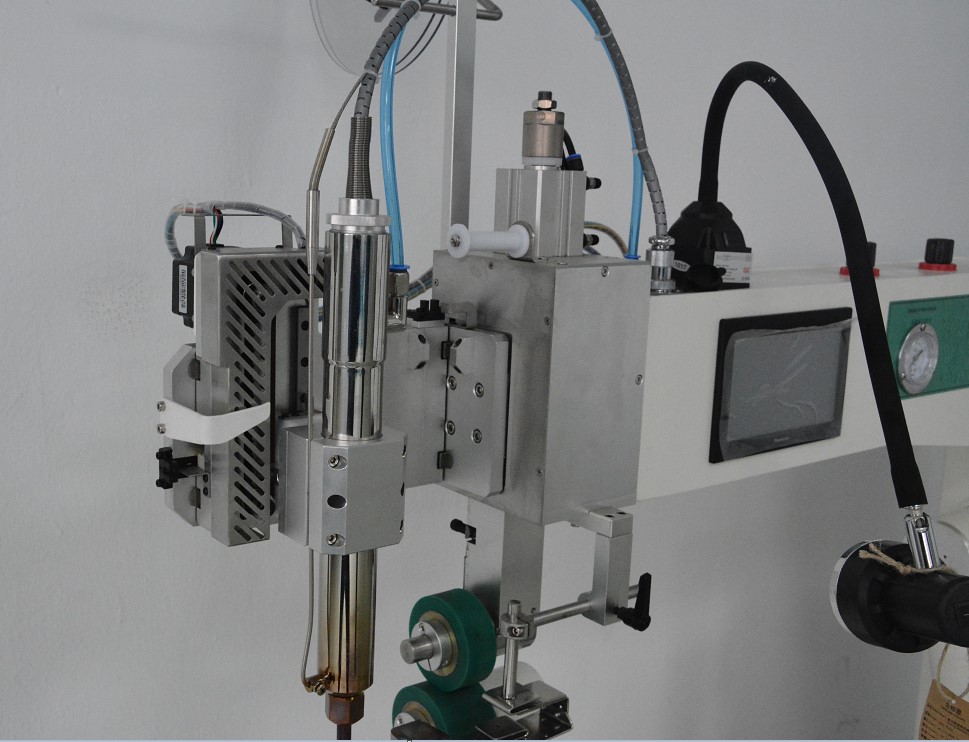

Product Description:

1.Bigger operation space,widely used in coated PVC fabric welding,such as tent house,inflatable boat/water tank,banner etc.

2. With both hot air and hot wedge function.

3. Editable PLC control,touch screen display.

4. Auto temperature control with warning device for the up limit temperature.

5. Auto compensation and reverse.

6. Double pedals control.

7. It could work up to 24 hours.

8. Blowing-in hot air is filtrated without any water and oil.

Introduction:

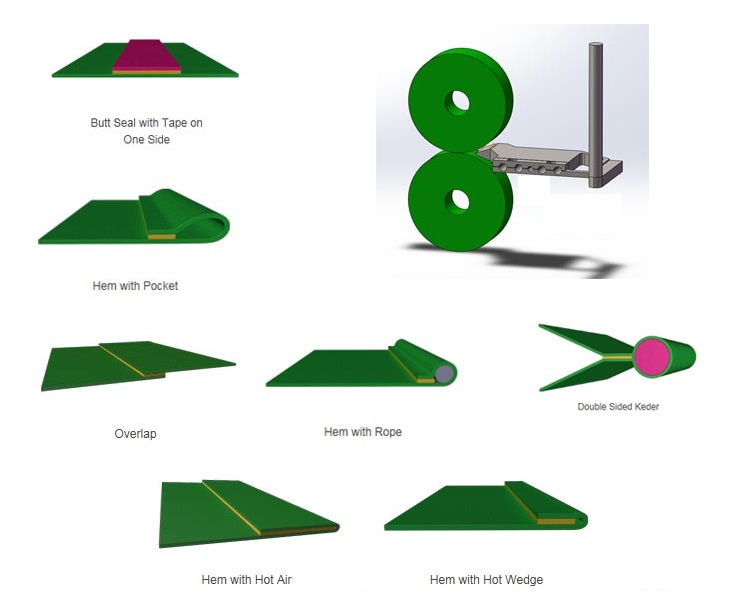

Hot air welding machine has unique advantage in inflatable products made of membranes structure, which is total different with high frequency welding and hot melt welding technology, the hot air is blew between the sealing surface, under necessary suitable pressure to get perfect welding effect, PVC, TPU material are all available, which are made to water polo, water drum, grass ball, inflatable swimming pool, large inflatable tents, inflatable boats, rubber boats and fishing boats and etc.

Purpose:

Hot air welding machine is suitable to produce all kinds of waterproof product which is made from coated PU,PVC,TPU, PE, PVA, such as large tent, inflatable boat and children toys, car covering,etc.

Welding material:

1.Vinyl (PVC) laminated fabric

2.Vinyl coated fabrics

3.Vinyl Films

4.Polyurethane film

5.Polypropylene coated fabric

6.Polyethylene (PE)

7.Thermoplastic rubber (TPR) film

8.Thermoplastic rubber fabrics

9.Nonwoven polyester

10.Various fusing tapes

11.Weldable webbings

12.Rigid extruded products